HOME > PRODUCTS & SERVICES

HOME > PRODUCTS & SERVICES

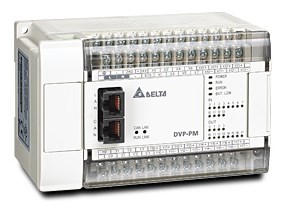

This series highlights high-speed command execution speed (basic command LD for 0.1375μs, application command MOV for 2.1μs and 1MHz differential output*4) to achieve precise motion control.

Used for 2-axis servo positioning control, material cutting machine (high-speed servo control), crane operations, material clipper controlled by the servo.

MPU points: 24

Max. I/O points: 256

Program capacity: 64k steps

Built-in hardware digital filter for counting

6 high-speed counters (O.C. 200kHz*4, differential 200kHz*2), supporting U/D, U/D Dir, A/B, 4A/B counting modes

4 differential 1MHz outputs, supporting U/D, U/D Dir, A/B output modes

Supports 1-speed (immediate stop after the mark arrives), 2-speed, zero return, MPG and single axis function

Highly accurate PWM 200kHz output, resolution 0.3%

Electronic gear function

8 high-speed captures (mark correction, frequency measurement), comparative output, mark/mask function (for bag making)

8 external interruptions for setting up rising- and falling-edge triggers, 1 timed interruption

Highly efficient command execution. LD: 0.1375μs, MOV: 2.1μs