HOME > PRODUCTS & SERVICES

HOME > PRODUCTS & SERVICES

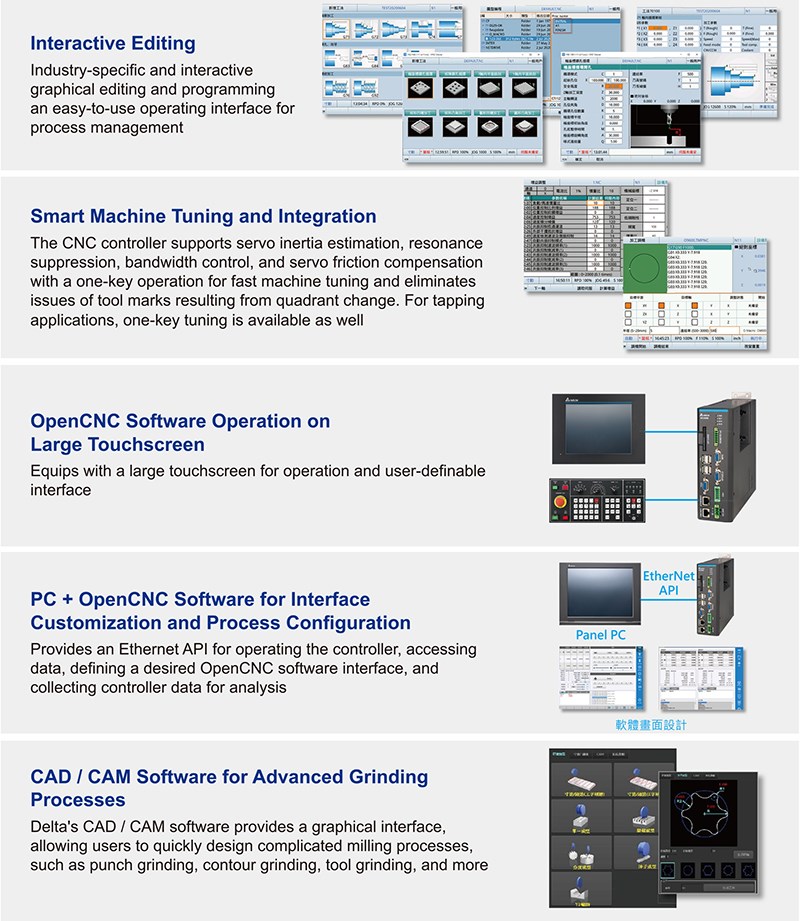

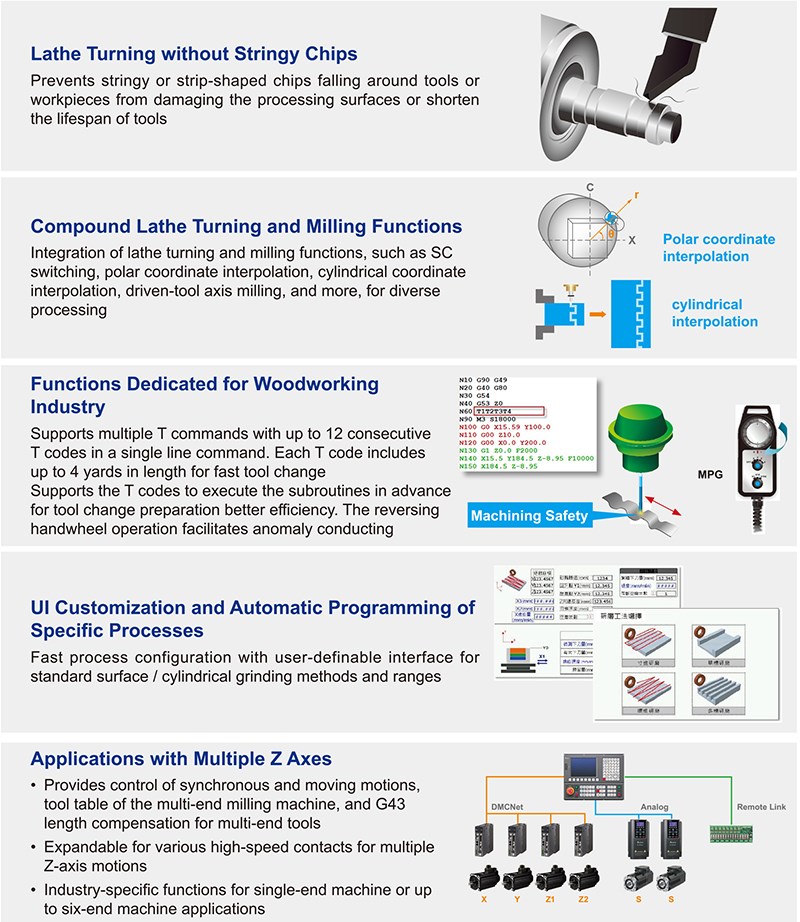

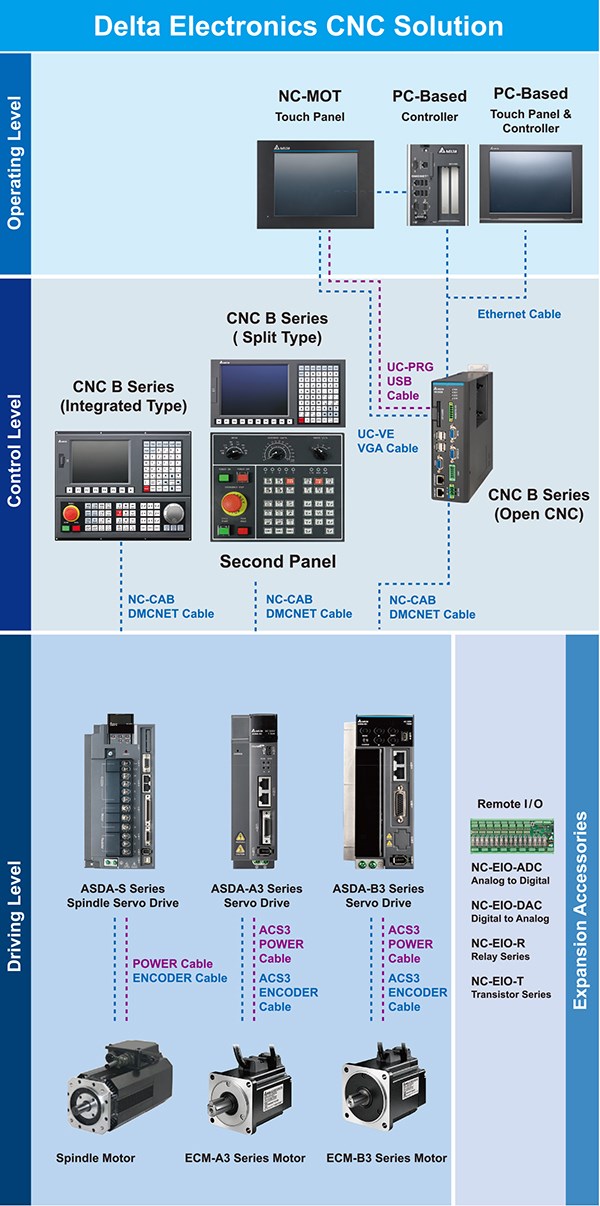

Delta's new general-purpose CNC controllers integrate a human machine interface (HMI) for developing a user-friendly operating interface and implementing customization requirements for industries. Built-in with Delta's DMCNET motion bus, the CNC controllers can fulfill highly precise, high-speed, and smooth processing with the AC Servo System ASDA-A3 Series or ASDA-B3 Series, permanent magnet (PM) motors / induction motors (IM) for the spindle, and encoders.

Built-in 32-bit high-speed dual CPU for multiple tasks and high performance

Implements data transmission and noise suppression with Delta's high-speed servo drives

Equipped with a high-resolution encoder with an accuracy of up to 0.1 um for smooth and precise motions

Automatic gain adjustment offers adequate motion control during machine tuning

A new operating interface built-in with the DOPSoft software for interface customization

A USB port for data access and parameter backup

Optional spindles of communication type or analog voltage type

The MPG function allows manual control of pulse input or handwheel input with a push button