HOME > PRODUCTS & SERVICES

HOME > PRODUCTS & SERVICES

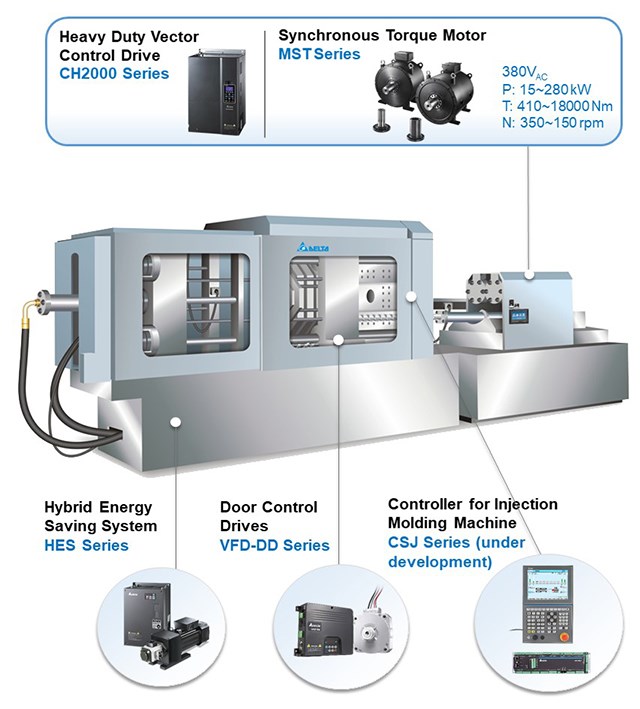

The Synchronous Torque Motor MST Series is designed for excellent performance at low speeds and is suitable for high torque applications. It implements synchronous motions with high-speed response for acceleration and deceleration to shorten processing time and achieve high productivity. Featuring a direct-drive mode and stable rotating speed, the MST series accurately controls plastic melting and the quality of plasticization, and enhances the yield rate for the fiber-reinforced injection as well. With high efficiency and high accuracy, it is applicable to miscellaneous shaft sleeves for various demands and applications.

The MST series is built with a robust structure for easy installation and maintenance and offers a longer lifespan. It is the perfect replacement for hydraulic motors or gear motors.

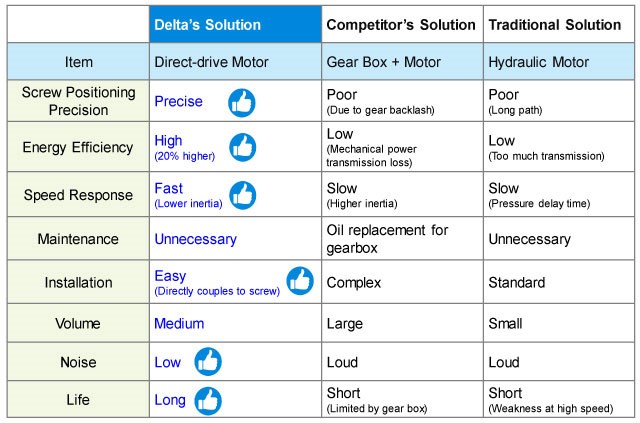

High efficiency: Reduces electricity cost up to 20% compared with hydraulic motors, and up to 10% compared with gear motors

Increased productivity: Synchronous motions along with hydraulic systems and high-speed acceleration / deceleration reduce processing cycle time and raise productivity

Low noise: Low noise generation without hydraulic motors or gear motors provide a better working environment

High quality: Direct-drive mode, no backlash, and accurate control of plastic melting

Stable rotation: Multiple motor poles for selection and stable rotating speed for high yield rate

Easy to use: Changeable shaft for various shaft sleeves

Longer life: Oil / water cooling extends motor life and provides easy maintenance

Hybrid Energy Injection Molding Machine Solution

Injection molding machines, hollow molding machines, blow molding machines, bag-on-roll machines, servo presses, printing machines, textile machines and more