HOME > PRODUCTS & SERVICES

HOME > PRODUCTS & SERVICES

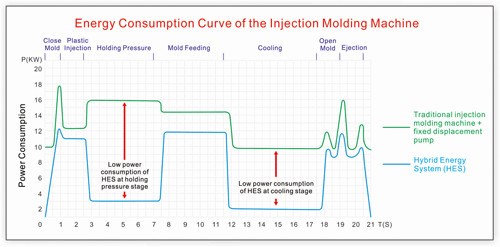

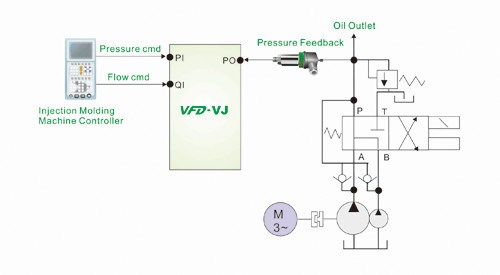

Delta's Hybrid Energy Saving (HES) System provides precise pressure and flow controls for each injection molding process and also solves the energy waste issues of a traditional injection molding machine. This solution helps to improve product quality, market competitiveness and productivity.

Superior Energy-Saving Outcomes: Lower energy consumption rate at the clamping and cooling stage while providing high productivity and high precision. 40% less energy consumption compared to a variable pump hydraulic systems. 60% less energy consumption compared to a traditional quantitative pump hydraulic system.

Low Oil Temperature: Oil temperature reduced by 5~10℃; oil usage reduced by 50~60%; requires 50% less oil tank volume; lower cooler specifications required and for some cases cooler is not required.

High Duplication Accuracy: Precise flow and pressure control featuring duplication of products with less than 0.09% difference.

Long Holding Pressure: Keeps mold halves securely closed for a longer period for thick plastic products formation.

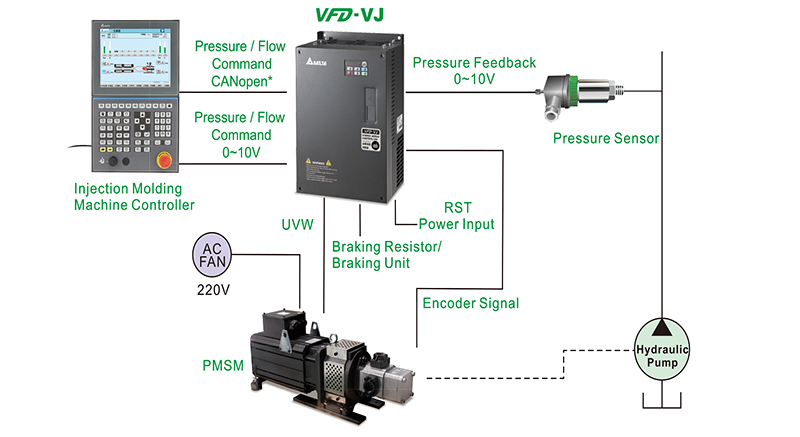

Good Frequency Response: When uses Delta HES with permanent magnetic servo motor (PMSM) speeds up frequency response to 50ms.

Suitable for Harsh Environments: The resolver used in Delta HES is resistant to earthquakes, oil and dust.

Old Machine Replenishment: Supports analog command 0~10V and linear correction (3 points), no replacing.

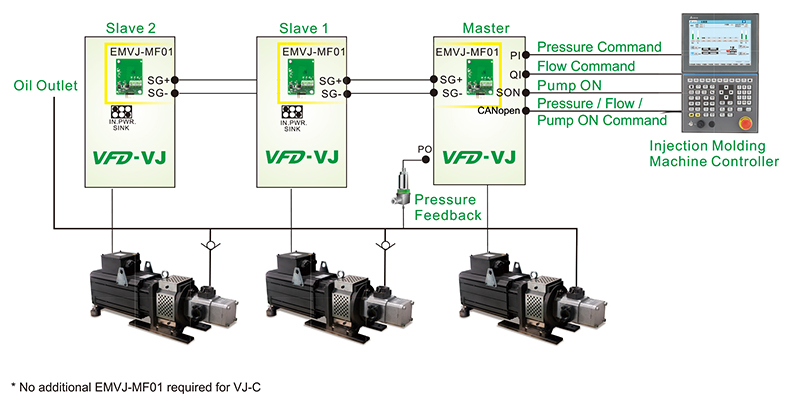

Flow Convergence: Saves cost on tubes, large flow capacity, enhances energy-saving.

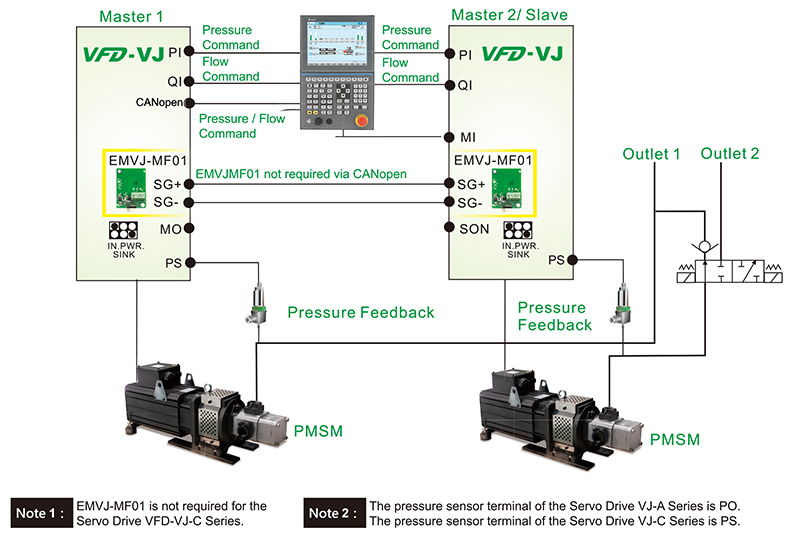

System Structure

Convergent Flow Multiple Pumps

Flow Capacity Switch

Convergent Flow / Divergent Flow

Injection Molding Machine

Die Casting Machine

Hydraulic Machine