HOME > PRODUCTS & SERVICES

HOME > PRODUCTS & SERVICES

Delta’s High Performance Compact Drive MH300 series is a new generation micro vector control that inherits Delta’s superior drive technology. With its advantages of outstanding drive performance, strong system support, and a variety of essential functions, the MH300 series is the key to improving market competitiveness and ensuring success. In addition, it features a USB port to make data uploads and downloads fast and easy, which saves the need for additional hardware and provides more installation space for the power cabinet.

Machine tools, textile machinery, woodworking, rubber and plastic, winding / unwinding applications

Outstanding Drive Performance

Overload capacity up to 150% / 60 sec, and 200% / 3 sec. Suitable for constant torque applications

Supports induction and permanent magnet motors with optional PG cards for highly precise speed and position control

Provides powerful torque output at low frequency (0.5 Hz / 200% without PG vector control; 0 Hz / 200% with PG vector control) for stable heavy-duty operation at low speed and high torque

Built-in constant tension control function

Speed, torque, and position control

Strong System Support

Built-in PLC with 5k steps; Supports system programming to save costs

Built-in STO (SIL2 / PL d) safety function and measures for sudden power outages

All models can be connected through a common DC bus

Built-in Modbus and CANopen interface; optional communication card, including EtherNet/IP, Modbus TCP, EtherCAT, DeviceNet, PROFIBUS DP, and PROFINET

Optional models with built-in filter

Optional 24V power supply card to reduce unexpected downtime

Flexible Expansion

Built-in two 33 kHz high-speed pulse input terminals (MI6 & 7) and one output terminal (DFM)

Built-in two accessory card slots for PG card, I/O expansion card, communication card, or 24V power card at the same time

Expandable to 3 DI and 3 DO, including 6 ports in total

Expandable to 2 or 3 relays

Advanced Tension Control

Built-in roll diameter calculation by linear speed, material thickness, and distance meter

Two PID parameters: Linearly adjustable to control tension at startup, of small / large rolls, and at high / low linear speed

Tension taper calculation: Automatically adjusts tension per the winding roll diameter to avoid wrinkles or deformation

Friction and inertia compensation for torque control: Automatically compensates friction and inertia during winding / unwinding for constant tension

Automatic roll change by merely using external signal without machine shutdown

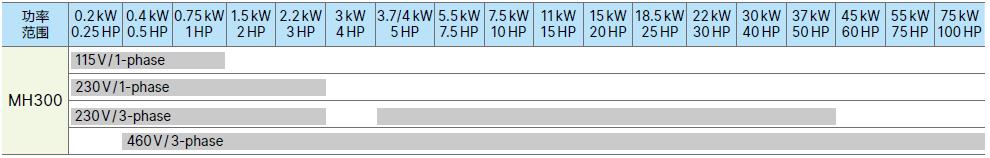

Power range